As online shopping practice around the world extended to such a degree that it brought even foods and prepared meals directly from the fields and kitchens and deliveredright at our doorsteps, packaging technology now plays an important role which has rarely been a part of the American farm and kitchen andthis is also true for most part of the world now.

But that ischanging in recent years as people started to consider creating their own start-up food companiesand expanding their small-scale production houses with more equipment and resources to meet the demand. Changes in state-level “Cottage Food” laws and increased interest in locally grown products has caused an enormous increase in homemade and Farmer’s Market products to go for retail sale. But, to do so, an efficient and cost-effective means of packaging of food products needs to be introduced which is economically viable to food start-ups and small-scale production unitsthose have limited resources and technical knowhow in automated product packaging field. LENIS MACHINES offers food packaging and production related machinery especially suited for food-startups, small and mid-sizedfood production and packagingunitsina budget and limited technical resource.

Food-startups, small or mid-sized food production and packaging units on the supply side of packaging can address this emerging market by recognizing what types of packages and packaging machinery and technologies it requires. The packaging community could be instrumental in this effort and use the following packaging attributes, machinery, and technologies where applicable and demandable:

Premade Bag Packaging UsingPremade Pouch Packaging Machines

There are variety of formed or premade flexible film-based pouches of different materials and geometriesavailablethat include Doypacks or stand-up pouches with zippers, liquid fitments attached premade Spout Pack bags of high-barrier materials for liquid products, lucrative Shaped-Cut premade standup or flatpacks, premade 4-side or 3-Side sealed bags or premade sachetsetc.

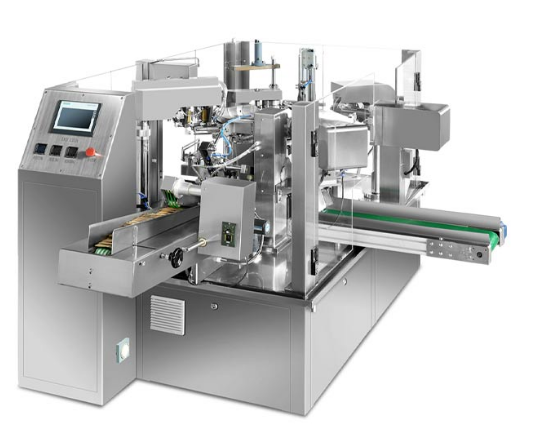

Rotary Premade Pouch Packaging Machinesare moderate to high-speed premade pouch packaging machines suitable for small to mid-sized food packaging businesses with a packaging speed of 20 to 60 packs per minute depending on the product, weight and bag size. Suitable for powder, grains, or granular items and liquid or pasty products.Generally,these automatic machines come in a line of machines includingAutomatic Material Conveying Equipment: Inclined Screw conveyors, Z-Bucket Conveyors, Automatic Filling Equipment: Auger Fillers for powder products, Multi-Head Weighers for grains, granular items and block products, Piston Pump Fillers for liquid and pasty products,Delivery Conveyors and Rotary Tables.

Rotary Vacuum Premade Pouch Packaging Machines are specialized machines for meat, fish and other food item packingin Doypacks, standup pouches and retort packs (as a modern alternative to canning process). These advanced machines fill the premade bags, vacuums them up to 99.9% and then seals the bags making easily perishable food inside tostore and keep fresh for a long time. These machines are replacing the canning process with retort pouches which are also known as soft-cans.

Stickpack, Stick-Bag or Small Sachets Using Stickpack Packaging Machines

Stickpack, Stick-Bag orSmall Sachets are made usingSingle-Lane Stickpack & Sachet Packaging Machines and Multi-lane Stickpack Packaging Machines for high productivity. Stickpack packing machines are a special type of VFFS machine that makes, fills and seals stick shaped packs from a roll of flexible film automatically.Multi-lane machines cut the wide films in slits according to the number of lanes the machine supports and then forms, fills with products and then seals the stickpack. These machines are getting very popular as single-serving products are becoming increasingly popular.

The single-lane stickpack packaging machines are preferred by the food startups as it requires small investment and good for testing a product in the market before going in full-fledged production. The multi-lane version of the machine is mostly used in high productivity environment and can come in the form of 4 to 18 lanes in a single machine. All these machines can pack powders, grains and liquid products with appropriate fillers.

These are just a few ideas that may be useful to startups andsmall-scaleto mid-sized packers as they grow. The manual packing machines with semi-automatic fillers can be very suitable for homebased packers using manual sealers.

Another thought is that this local food production and packaging could be viewed as a means to improve food protection at the household level and could be applied to developing areas where food loss is a key concern. Automating food packaging machinery can improve food hygiene, quality,freshness, and shelf-life of the food a lot.Save Food is an international effort to bring these types of ideas to the table, and maybe the Packaging community could be instrumental in this effort.